Capability Statement

Building on the success and resilience of 2022, we have a number of important focuses in 2023 that will keep us growing sustainably

Staticus Group Capability Statement for 2022 Photo © Andrius Gudelis

Contents 01 Letter from 02 About 03 Corporate group CEO Staticus Sustainability 8 The group committed to the long term 16 Putting Staticus Sustainability strategy into action 9 Business regions 18 Sustainability Highlights 2022 10 A value chain delivering 19 Sustainability Goals 2023 customisation and efficiency 22 Health and Safety of employees 11 Legal information 24 Active philanthropy 12 People are our priority 14 An overview of the years 04 R&D Activities 05 Key 06 Financial Results & and Digitalization projects Business Plans 26 Major steps forward in key 34 Hospitals 64 Short introduction to Corporate Finance R&D projects in 2022 41 Refurbishmen 66 Business plans and Group forecast 30 A new framework for Agile 46 Closed Cavity 32 Digitalizing Staticus 53 Highrise buildings 60 Facade with timber cladding

Letter From the Group CEO Go to contents 3 Healthy financial results secure Staticus consolidates and our long-term future grows in 2022 thanks to its Our commitment to the long-term and our extremely resilience and agility “talented team enabled us to secure consistent growth and profitability in 2022, in line with our 3 year strategy. Our turnover grew from €62 million to €80 Nevertheless, the direction and mood of million. This growth was delivered not with the year was heavily impacted by Russia’s a higher volume of projects, but with higher invasion of Ukraine in late February. Along value projects. Indeed, the average value with the personal impact this had on us all, Aušra Vankevičiūtė / of our projects increased to €15 million, it also represented another major disruption Group CEO, Staticus and we secured our highest value project for our operations following COVID-19 and to date, the over €47 million facade for the the upheaval in the supply chain that had Landspítali Hospital in Iceland. impacted us in the previous two years. The focus of our management team in 2022 Initially, it was impossible to tell what the was on ensuring stable income and revenue impact of the war would be: how long with a high priority on cash flow. I am very it would last or what it meant for the proud of our management team, and the geopolitical situation. Furthermore, many of fact that our quite conservative approach in our team were understandably scared and rd For the 3 year in a row, I am starting my letter by largest-ever contract, enter new markets, grow uncertain times has yielded a very healthy unsettled. Meanwhile, the markets reacted writing that this was a year like never before. our annual revenue, and expand our team. We financial result. We remain unleveraged and and many developers started to reconsider remain unleveraged and in a healthy financial have good liquidity ratios. investments in new projects. After the turbulence of COVID-19 and global position, which gives us something hugely We benefited from the fact that we had supply chain disruption, 2022 saw the outbreak valuable in these turbulent times - security. This Prioritising resilience and long-term taken the strategic decision years before of war and the subsequent crises in energy and means safety and stability for our people and stability in volatile times to build our supply chain without using material prices. I am immensely proud that, in our clients, and is the foundation for all of the companies from Russia or Belarus. the face of these challenges, Staticus once again valuable work we do in R&D and sustainability, 2022 started very positively for us, with Nevertheless, material prices, including the launch of our corporate sustainability glass, increased after the onset of war, demonstrated its resilience. Our team was agile, and in delivering benchmark-setting projects. strategy and an extensive rebrand (more on and the energy crisis followed. Our teams tenacious and creative, enabling us to secure our those in a moment). worked exceptionally hard and effectively

Letter From the Group CEO Go to contents 4 to manage the situation, and I would also A sustainability strategy rooted in Reevaluating our approach like to thank our clients for their cooperation partnership and long-term thinking to negotiation and understanding. We were able to openly share each other’s pain points, and to also 2022 saw the publication of our corporate Another of our sustainability focus areas, share costs so that no single party was sustainability strategy. In our 3 year strategic Partnership, led us to reconsider the way we shouldering all of the costs. cycle formulated in 2020, we committed to approach negotiation with the help of leading becoming leaders in sustainability. We spent negotiation strategist Keld Jensen. Our The situation stabilised after two or three 2 years understanding the market’s needs, aim is to be profitable, and for our partners months. Some projects were put on hold, developing an extended view of what our to be profitable as well, which is especially others continued, and new projects came up sustainability offering should encompass important in a sector with low profit margins as well. Nevertheless, even with the situation that goes well beyond simply looking at CO2 like construction. stable, it was necessary to prioritise emissions or planting trees. business resilience and long-term stability in Working together with Keld Jensen and terms of the projects we took on. Therefore, We then cooperated with the Swiss exploring his Smartnership framework, we made a strategic decision to focus more sustainability consultancy, Sustainserv, who we looked into ways to find hidden value in on governmental projects, and ensure all guided us through the development of our negotiations that create win-win situations. projects we took on had secure cash flow. sustainability strategy and helped us identify Achieving this requires a high level of 5 focus areas: transparency. Furthermore, both parties need As a result of this approach we now have to have a mindset that is oriented around three major hospital projects secured in the 01 Transparency teamwork and delivering the project in the Nordic region: the Radiumhospitalet in Oslo, best way possible. the 118,000m2 North Zealand Hospital in 02 Partnership Denmark, and most the Landspitali Hospital We look forward to launching our corporate in Iceland impressively our first project in 03 Innovation in Design and Delivery negotiation strategy in 2023, which will Iceland and our largest to ever in terms of provide guidelines for our organisation, and contract value (€47 million). 04 Climate Protection we hope will become a benchmark for the industry. These projects, and the many others 05 Being a Sustainable Organisation we have secured and are working on, represented a double victory for our Each of these focuses was then broken Continuing our Agile journey company in 2022. Firstly, these are exciting down into specific elements. For example, projects in important markets that keep us included within the Transparency focus area In 2022, we decided to change gears in our at the cutting edge of façade design and is a commitment to business resilience journey of becoming an Agile organisation. technology. Secondly, they ensure our long through risk and cost management. After This included developing a new Agile term resilience and stability thanks to their all, there is no point in having amazing framework, and continuing to listen closely to scale and government backing. sustainability initiatives if our company is not feedback from the cross-functional project around for the long-term to deliver on them. teams that are now using Agile methods.

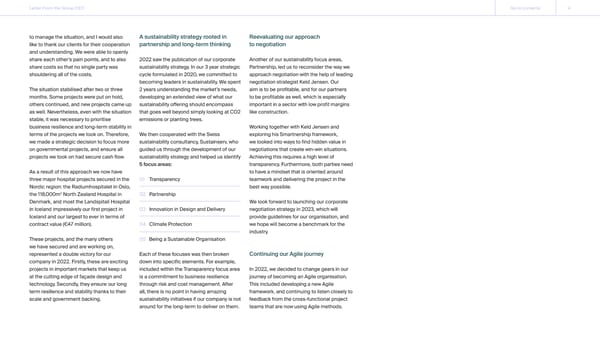

Letter From the Group CEO Go to contents 5 Moving from a typical hierarchical structure Finally, in 2022 we organised the creation to a team-based one sounds simple. In of our own testing rig, that will be CWCT and fact, it is a complex long-term shift that EU compliant. This rig will be a major step involves structural changes, and shifts in forward in terms of our in-house knowledge our mindset. I am very happy that we have and Quality Assurance processes, as it will open-minded people who are ready to be enable us to perform continuous in-house ambassadors of change. tests. The rig is set to be completed in Q2 of 2023. Progress in major R&D projects A new look and ongoing digitalization I am proud that in 2022 Staticus still managed to make significant progress in As we take a leading role in areas such our amazing R&D projects, despite the as sustainability and Agile working, it is unpredictable context. important that we share our ideas and actions with a wide audience. In 2022, we Together with our project partners KTU, relaunched the Staticus brand with a fresh SINTEF, and Oslo Met, we conducted visual look and fresh perspectives to share extensive research into IoT and digital twins, as well. We have received very positive and worked on developing our hybrid façade feedback, and this rebrand has helped to product that combines recycled aluminium amplify our voice in the sector. with timber. While we are keen to bring this solution to market - we see significant 2022 also saw a focused continuation of demand for it - we are also exercising a the digitalization that is essential for our careful approach. We are responsible for business. For example, we launched our developing this technology, and therefore new 4D tool that enables stakeholders to need to test it thoroughly in cooperation easily view progress data on a project. with researchers and be sure that it meets our quality standard. Another major step forward in our R&D activities in 2022 was the launch of our own system for designing and creating aluminium profiles, which was already used on the Separatorn 1 project in Stockholm. Landspitali University Hospital | Reykjavik, Iceland VVisualisatisualisation © Cion © Corpus 3 deorpus 3 design grsign groupoup

Letter From the Group CEO Go to contents 6 Key focuses for Strategic cycle completion R&D Sustainability, talent Staticus in 2023 and transformation A 3 year strategic cycle will be completed 2023 is set to be another intensive and at the end of 2023. Therefore, one of our exciting year in terms of our R&D activities. In terms of our sustainability activities, main focuses for this year will be to ensure We will continue with the development of 2023 is all about implementation. We Building on the success and that we have delivered what we committed our hybrid facade. This will include building are now in the process of defining the to 3 years ago. In terms of revenue, we are a prototype and then demolishing part of KPIs for each of the focus areas in our resilience of 2022, we have a number on track to achieve our goal of EUR100 a wall in our facility so we can install the Corporate Sustainability strategy, and we of important focuses in 2023 that will million annual turnover in 2023. Our market prototype and test how the IoT sensors are working out how to measure these so penetration is also on track, and our focus work in a real environment. We also expect we can provide full transparency and clarity keep us growing sustainably. in 2023 will be on maintaining the current to complete the construction of our testing on exactly how we are acting sustainably. number of markets we have, with some rig in 2023. We also intend to expand Additionally, our Sustainability Lead, slight growth planned. For example, we will the number of universities and research Anastasiya Popova, will continue her work look to further expand in the UK market institutions we cooperate with. on the CWCT sustainability workstreams and plan to add to our team there, and we committee for embodied carbon in facades. also hope to secure our first projects in the I believe that these activities, and our long Benelux and Swiss markets. term commitment to R&D, is boosting Our continued transformation into an Agile the innovation mindset within Staticus, organisation will continue, with the ongoing Naturally, our attention will then turn to the providing a space similar to a playground reorganisation of our teams and working next strategic cycle, which runs from 2024- where people can test, try and experiment. practices. In 2023, we will put in place clear 2027. As usual, we are encouraging all descriptions of roles and responsibilities Staticus employees to actively participate in within this new framework. the process of formulating our new strategy. We have already formed a strategic team of employees from different departments. This team was formed based on the insights they provided and their desire to contribute to the development of our strategy. We will once again be enlisting the help of the prestigious Swiss business school IMD with formulating our strategy.

Go to contents 7 About Staticus 02 The group company committed to the long term Business regions Taking façades from concept to reality through and end-to-end value chain Legal information People are our priority An overview of the year

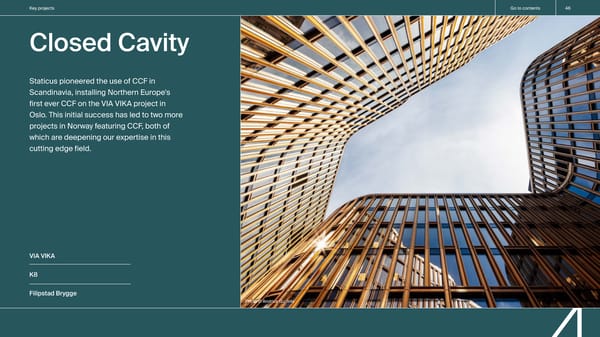

About Staticus Go to contents 8 Staticus is a leading façade contractor in Northern Europe. The group We leverage our over 20 years of experience and our strong competencies in innovation to deliver benchmark-setting committed to projects that maximise long-term value for our clients and for society. the long term As a family-owned business that has And we commit to people. We subscribe Our offices and markets grown and developed sustainably over to the very highest standards of health more than two decades, we understand and safety in the industry in order to keep Staticus is a truly international group, and the importance of having a long-term our team, our partners, and the public we continue to expand our presence both in perspective. safe. Our people-first culture within the terms of where our team is based and which group aims to create the conditions for markets we operate in. We have delivered, We commit to our partners, building close every team member to develop and thrive. or are currently working on, projects in and collaborative relationships with the 7 different countries: Norway, Sweden, clients and suppliers we work with. This Denmark, Finland, the UK, Iceland and includes taking a proactive approach to Consistently delivering innovative, Lithuania. And we have active operations in each project we work on. Our experienced high-quality façades the Netherlands, Belgium and Luxembourg. team provides early stage interventions to ensure the best possible result in terms This long-term approach is what enables Our international team has 7 offices at of architectural vision, performance, and us to consistently win and implement present. Our headquarters and production sustainability. benchmark-setting projects. facilities are in Vilnius, Lithuania, and our sustainability team are based in Basel, We commit to our planet. Our dedicated We now have a very strong track record Switzerland. We also have offices in London, sustainability team oversees each project, across the Northern European market, Vienna, Kaunas, Oslo and Stockholm, and assessing the carbon footprint of the and a reputation for going the extra our team members come from all 4 corners façades design and produce. And our end- mile. We have delivered the first ever of the European continent. to-end value chain enables us to implement project in the region to use Closed Cavity genuine life-cycle thinking. Furthermore, we Façade technology. And, with our R&D are constantly improving the environmental team working on new innovations in IoT performance of our facilities and dedicating and hybrid façades, we aim to continue time and resources to developing lower- leading the way in the façade industry. carbon façade technologies. Stockholm New | Stockholm, Sweden

About Staticus Go to contents 9 Committed across Europe Offices and Markets Markets Staticus Norge AS Ofices Norway Staticus Sverige AB Sweden Our main operating regions are Norway, Sweden, Finland, Denmark, the United Kingdom, Iceland, Austria, Switzerland, and Lithuania. The company’s headquarters, as well as our design and production divisions, are located Staticus UAB in Lithuania. Staticus also has offices in Lithuania Oslo, Stockholm, London, Basel and Vienna. Staticus UK Ltd. United Kingdom Staticus Austria GmbH Staticus Schweiz AG Austria Switzerland

About Staticus Go to contents 10 Staticus’ end-to-end value chain enables us to Our continued evolution as an Agile organisation also enables us A value chain delivering ensure the architectural and performance goals for to effectively deliver an end-to-end service. Having developed a each project are met. new Agile framework in 2022, our teams are cooperating more customisation and effectively than ever, which ensures seamless and rapid project Our ability to take façade projects from concept design right delivery. efficiency through to installation and aftercare is built on our high levels of digitalization. Our new 4D reporting tool enables stakeholders to Armed with advanced digital tools and an Agile work process, our track a façade’s progress at every stage. With updates 3 times per team of over 110 engineers with skills in R&D, design, production day and data integrated with 3D models, this tool provides up-to- and installation, are able to handle the whole process of even the date information that is simple to understand. most complex projects. We offer services at the following project stages: 01 Concept design 02 Design development 03 Mock-ups and testing 04 Production 06 Installation 2 We collaborate closely and engage as At this stage of the process, we work We are able to produce a wide range of Our 12,050 m production facility can host Our focus on installation begins at the early early as possible to ensure the right through each individual design question mock-ups so that project partners can up to 12 assembly lines, enabling us to work design stages. This enables us to deliver customisations are made to meet each and problem solve. Other important see and assess the aesthetics, materials on multiple projects simultaneously and a smooth, continuous installation that project’s unique needs. This includes activities at this project stage include and performance of the façade units. This deliver highly complex, customised projects maximises our use of on-site time while early stage consulting, concept design feasibility consulting, structural and physical includes the production of Performance on time. Our average annual production never compromising health and safety. 2 development, advice on technical feasibility, calculations, parametric design, workshop Mock-Ups (PMUs) for testing at facilities capacity is 150 K m of façade units. and budget and cost planning. design, installation drawings, and as-builts. in Germany and the UK. In 2022, with the support of Norway Grants we completed planning and preparation for a new testing rig at our production facility. The rig, which will enable us to run full test sequences that are aligned with CWCT and European 05 Logistics standards, will be completed in Q2 of 2023. Our logistics specialists work closely with site managers to develop plans that It will also further enhance our in-house minimise on-site storage. Completed quality assurance, ensuring that every façade units are delivered using just-in- project is verified via physical testing before time supply, and façade unit storage is also production starts, and then continuously available at our facilities. during production itself.

About Staticus Go to contents 11 About staticus’ own shares Board members Information on research Legal and development activities In 2022, none of the companies of the Chairman of the Board Andrius Smaliukas, of the companies of the group Group held their own shares, nor did they Law Firm Milašauskas, Martinkutė, acquire any during the reporting period. Smaliukas and Partners. Developing a more environmentally friendly information Address: Gedimino ave.10, Vilnius, Lithuania. automated façade system that is integrated Position: lawyer, managing partner. The into the building’s control systems. office does not have a company registration Information on divisions code because it is not a legal entity. Together with OsloMet and SINTEF, Staticus Reference and further explanations and representative offices is working on a ConTech project aimed of the data presented in the annual of the group companies Aušra Vankevičiūtė, UAB STATICUS Group. at reducing the construction industry’s Address: Metalo str. 13, Vilnius, Lithuania. share of greenhouse gas emissions. By financial statements In 2022, Group company UAB Staticus Company registration code: 303354911. substituting aluminium systems with timber registered an office in Finland. Position: CEO. and integrating IoT sensors, we seek The information presented in the Group’s consolidated to decrease the façade’s CO2 footprint annual financial statements is complete and accurate. Paulius Stonkus, UAB STATICUS Group. by 70-75% and non-renewable energy Address: Metalo str. 13, Vilnius, Lithuania. consumption by 53-56%. Information about Company registration code: 303354911. the management Position: Chief Legal Officer. On 8 May 2019, Aušra Vankevičiūtė Tomas Bučas, Staticus Sverige AB, Financial risk management was appointed the new CEO Engelbrekts väg 6, 19162 Sollentuna, information of UAB STATICUS Group. Sweden. Company registration code: 5567477129. Position: Sales Director The Group is exposed to foreign exchange Nordics. risk and uses derivative financial instruments to manage this. Information on significant events that have occurred after the end of the financial year There were no significant events in the Group, the nondisclosure of which could have a significant impact on the decision- making ability of the users of the Group’s consolidated financial statements.

About Staticus Go to contents 12 We actively support and listen to each member of our team, People are encouraging them to grow as professionals. Ultimately, it is our people who enable us to deliver benchmark-setting our priority projects. Thanks to them, we are a resilient and innovative organisation that continues to meet the needs of our clients. Broad horizons and fresh perspectives We have a well-developed mentoring a safe, supportive and collaborative work setup in place for new hires. Moreover, we environment: Members of the Staticus team gain work to ensure inclusion by implementing fresh perspectives that broaden their progressive work methods, and regularly — We implemented a leadership professional horizons. They work on unique evaluate our processes and structure to development programme. This included projects in new markets - in 2022 we make constant improvements. training, workshops, and other of secured our first project in Iceland - and are collaborative activities; part of a diverse international team. Key achievements in 2022 — To support our employees’ physical They also have regular opportunities to and emotional health, we put on talks share their perspectives thanks to our Agile We made substantial progress in 2022 on subjects such as time and task setup and open company culture. This both in growing our team and in ensuring management, civil defence, effective enriches our organisation and ensures the our work culture is set up to help each meetings, and the importance of best ideas and practices are heard. employee thrive. sleep. We also offered our team free consultations with a psychologist. We welcomed 133 new colleagues. Long-term commitment to our staff Furthermore, we were very pleased that 32 — To foster a work culture based on former employees chose to rejoin our team. curiosity and learning, we continued As a company, our goal is to have a long- a number of programmes, including: term impact. To do this, we must be fully These new and returning colleagues knowledge-sharing afternoons, “Staticus committed to our employees. brought our total team size to 626 Goes Digital” (a forum where employees employees. can share the digital tools they use), and We build tight-knit and collaborative teams, an employee book club. and create a supportive culture where As our team grew, we undertook a team members can experiment and learn. number of important initiatives to ensure

About Staticus Go to contents 13 Becoming Purpose-Driven — the organisation’s capability to 20 Staticus employees from different 626 implement its mission and the level departments will participate in the Design & In 2022, we started on our journey towards of commitment of its leaders; development of our new strategy; employees: 117 Engineering becoming a purpose-driven organization. The term “purpose” describes a — which HR practices and management — To continue developing our company’s driving force: the contribution areas need to be developed or competencies in three strategically PM & it makes to society and the impact it wants reevaluated in order to strengthen unity. important areas: technical competence, 29 Estimation to achieve. project management competence, and This survey, and our work to act on its leadership; Research has shown that purpose-driven findings, will help us to strengthen each Procurement & businesses perform better. They generate person’s link with the organisation and — To further develop and strengthen our 53 Supply Chain Division more income, and have more engaged improve cooperation between employees. cooperation with educational institutions employees and more loyal customers. in different countries; This is because they are better at Focuses for 2023 — And to continue creating more user- 71 Administration innovation and transformational change. friendly tools for our team, including self- They also have a team that is all pulling the Staticus has clear goals for 2023 service tools and the Staticus intranet, same direction, as their purpose becomes with regards to its employees: as part of the company’s ongoing Production the overarching orientation against which digitalization. 356 & Installation teams and employees can measure and — To continue to improve our business align their decisions. agility at all levels of the organisation by changing to a team-based structure; Our activities in 2022 — To focus further on becoming a purpose- driven organisation; We invited the consulting company CRC Consulting and the University of Navarre — To maintain and strengthen our company to carry out an Organisational Unity Survey. culture, in particular our client-centricity’ These surveys cover a wide range of areas including: — To co-create our new strategy for 2024- 2027 together with Staticus employees — whether employees’ perceive an and in cooperation with IMD, a Swiss- organisation’s mission as their own and based independent academic institution the consistency between personal and ranked in the Top 3 globally by the FT organisational values; for Executive Education. More than

About Staticus Go to contents 14 An overview of the year We signed a contract worth We won tenders for 5 new projects We welcomed 133 new and We welcomed back our former CFO €47 million for the Landspítali Hospital which together have a combined value 32 returning colleagues, bringing Ignas Stasiukonis, who rejoined in Iceland. This is the largest project in of over €100 million. our total team size to 626 employees. the team as our new COO. Staticus’ history in terms of contract value, and also our first ever project in Iceland. We implemented and launched We developed and implemented We started implementation of our We were actively involved in CWCT a rebrand which included repositioning a new Agile framework to continue our Corporate Sustainability strategy, sustainability workstreams and the development of new visual transformation into an Agile organisation. which is oriented towards 5 key focus areas: dedicated to establishing industry standards elements. transparency, partnerships, innovation in for embodied carbon calculation and using design and delivery, climate protection, and Environmental Product Declarations. being a sustainable organisation. We developed a new negotiation We maintained our great health and We actively participated in an international project strategy with renowned negotiation safety record, with zero serious or together with Oslo Metropolitan University (OsloMet), expert Keld Jensen to enable win-win fatal accidents. Kaunas University of Technology (KTU) and SINTEF, agreements with our partners. focused on the development of a hybrid façade system, new testing facilities, and sustainable IoT solutions.

Go to contents 15 Corporate Sustainability 03 Putting our Sustainability strategy into action Sustainability Highlights 2022 Sustainability Goals 2023 Health and Safety Active philanthropy

Corporate Sustainability Go to contents 16 Through corporate sustainability we create long- In 2021, we concluded Staticus’ Corporate Sustainability Putting Staticus term value, focusing on the social, environmental, Strategy for the upcoming years. In 2022, we moved to and economic dimensions of doing business. its implementation phase. Our Corporate Sustainability Sustainability strategy Strategy consists of 5 key focus areas: transparency, Our commitment to sustainability and long-term partnerships, innovation in design and delivery, climate into action thinking manifests itself in clear, concrete actions. protection, and being a sustainable organisation. 1. Reporting / Communication: 1. Sustainable mindset as 1. Monitoring of legislation 1. Product carbon footprint 1. Education and Training. Establish sustainability a foundation for partnerships. on sustainable construction. Establish a platform for project- Sustainable Mindset; reporting on material topics; 2.Supply chain management: 2.Low Carbon Systems. specific analysis. Talent development; Develop customer-specific ESG risk analysis of supply chain; 3.Long-term engagement. 2.Value chain analysis of carbon footprint: Reskilling. reporting. Roll-out ESG compliance criteria 2.Cross Functional teams. 2.Compliance: and monitoring; 4.Circular Economy: Estimate scope 1, 2, 3 emissions; Use supplier assessment platform Design for disassembly and reuse; Development of carbon reduction 3.Diversity and Inclusion. Monitoring of legislation; for management. Zero waste: targets incl. supplier engagement. 4.Engagement. Labor practice; Health & Safety: zero accidents. 3. Cooperation with research Optimise in-house waste management; Employee engagement; 3.Business resilience: and educational institutions. Optimise site waste management; Community engagement Operational efficiency. Risk management; Cost management.

Corporate Sustainability Go to contents 17 Sustainability In 2022, we took steps forward in the implementation of each sustainability objective according to our 5 sustainability focus Highlights areas. The summary below provides highlights of our activities. Our Sustainability Report 2022 gives a comprehensive 2022 overview of the current situation in each area. 01 Transparency implemented projects. The goals for the contains questions about our suppliers’ future are outlined with short-term and long- sustainability strategies, which low-carbon At Staticus, we provide transparency term targets. products are available, and sustainability through sustainability reporting on material documentation such as Environmental topics. Reporting is a vital component of Product Declarations. The purpose of the our sustainability activities, because it 02 Partnerships survey is to analyse the sustainability risk of ensures we remain accountable and keeps our supply chain and assess the status quo, us focused on continual improvement. We build long-term relationships with our with the final goal of engaging our suppliers This year, for the first time, we prepared clients, partners and suppliers, and the in the development of carbon reduction comprehensive sustainability reporting foundation for these is always a mindset targets. according to the 5 focus areas of our focused on being sustainable. With our corporate sustainability strategy. suppliers, we collaborate closely to not only meet sustainability specifications, 03 Innovation in Design The Sustainability Report 2022 provides but to develop carbon reduction targets a detailed account of our activities and that accelerate our progress and exceed and Delivery performance over the year. The progress industry-wide common practices. in each sustainability objective from the We have been building a portfolio of low- 5 sustainability focus areas is thoroughly In 2022, we developed a digital carbon R&D systems that are tailored to described with KPIs, statistics and sustainability survey. This survey meet and exceed the relevant sustainability Økern Portal | Norway, Oslo Photo © Andrius Gudelis

Corporate Sustainability Go to contents 18 specifications (the R&D section of this Calculator provided by the Supply Chain the Steering Committee that consists of the report provides more information on these). Sustainability School. This analysis showed representatives from the Board of Directors. In 2022, we extended our R&D activities to that 97% of the company’s total carbon Consistent financial performance in the embed circular economy principles into our emissions originate from materials usage. past years is the foundation for the Group’s façade design. The remaining 3% come mainly from sustainable work. factory operation and transportation. These We conducted a disassembly exercise of results demonstrated the importance of Our revenues have increased significantly a unitized façade system in a sequence engagement with our suppliers and the over the past year, driven by our successful based on the component’s lifetime. During availability of low-carbon raw materials efforts to expand our customer base and this exercise we identified critical system in the market to achieve carbon footprint increase sales. In addition, we have carefully components in terms of accessibility and reductions in the end-product. managed our expenses and invested in potential for replacement or reuse. Then, strategic initiatives that have helped us in collaboration with the Dutch façade Additionally, in 2022 we were actively improve our operations and drive further consultants Frontwise, we determined involved in CWCT sustainability growth. the disassembly rating of a state-of-the- workstreams dedicated to establishing art unitized façade system to quantify the industry standards for embodied carbon We are confident that this success will impact of design changes on the overall calculation and using Environmental continue into the future for several reasons. disassembly potential. The results of this Product Declarations. First, we have a clear and focused strategy exercise are being used to develop the next that guides our decision-making and helps generation of low-carbon R&D systems that us stay aligned with our goals. Second, take into consideration disassembly and 05 Sustainable Organisation we have a talented and dedicated team of reuse criteria. employees who are committed to delivering We foster a sustainability mindset within high-quality products and services to our employees and cascade sustainability our customers. Finally, we have a strong 04 Climate Protection objectives into the organisation. In financial foundation that allows us to 2022, to accelerate implementation of weather market fluctuations and invest in As an end-to-end façade contractor, we are our sustainability strategy, we formed a long-term growth. in a strong position to minimise the carbon Sustainability Committee consisting of 16 footprint of our own operations, and of each members representing each division in the In summary, we are proud of our consistent project we work on. We thoroughly assess company. This way, each division started to financial performance over the past the entire life cycle of the products we own and report on sustainability objectives year, and we believe that this success produce, a process which begins with the to the Sustainability Lead. The Sustainability is sustainable due to our clear strategy, purchasing of raw materials and runs all the Committee works in an agile way and talented team, and strong financial way to the end-of-life phase of every façade. meets on a bi-weekly basis to discuss the foundation. We look forward to continuing progress of sustainability-related initiatives, to deliver value to our customers and In 2022, we estimated our value chain’s resolve issues and define next steps. The shareholders in the years ahead. carbon footprint using the Carbon Sustainability Committee is governed by

This is a modal window.

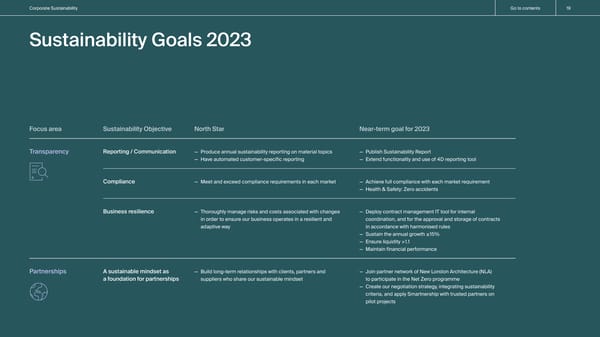

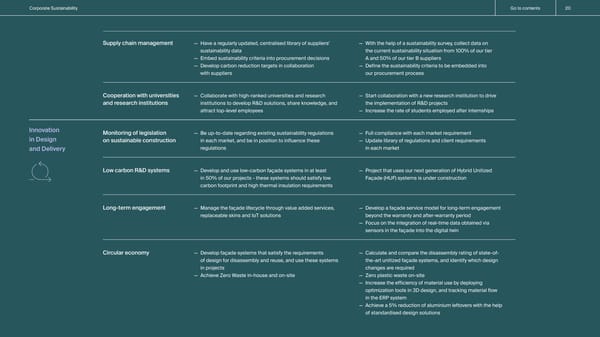

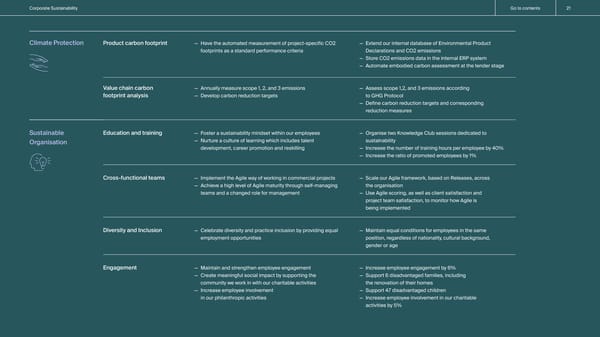

Corporate Sustainability Go to contents 19 Sustainability Goals 2023 Focus area Sustainability Objective North Star Near-term goal for 2023 Transparency Reporting / Communication — Produce annual sustainability reporting on material topics — Publish Sustainability Report — Have automated customer-specific reporting — Extend functionality and use of 4D reporting tool Compliance — Meet and exceed compliance requirements in each market — Achieve full compliance with each market requirement — Health & Safety: Zero accidents Business resilience — Thoroughly manage risks and costs associated with changes — Deploy contract management IT tool for internal in order to ensure our business operates in a resilient and coordination, and for the approval and storage of contracts adaptive way in accordance with harmonised rules — Sustain the annual growth ≥15% — Ensure liquidity >1.1 — Maintain financial performance Partnerships A sustainable mindset as — Build long-term relationships with clients, partners and — Join partner network of New London Architecture (NLA) a foundation for partnerships suppliers who share our sustainable mindset to participate in the Net Zero programme — Create our negotiation strategy, integrating sustainability criteria, and apply Smartnership with trusted partners on pilot projects

Corporate Sustainability Go to contents 20 Supply chain management — Have a regularly updated, centralised library of suppliers’ — With the help of a sustainability survey, collect data on sustainability data the current sustainability situation from 100% of our tier — Embed sustainability criteria into procurement decisions A and 50% of our tier B suppliers — Develop carbon reduction targets in collaboration — Define the sustainability criteria to be embedded into with suppliers our procurement process Cooperation with universities — Collaborate with high-ranked universities and research — Start collaboration with a new research institution to drive and research institutions institutions to develop R&D solutions, share knowledge, and the implementation of R&D projects attract top-level employees — Increase the rate of students employed after internships Innovation Monitoring of legislation — Be up-to-date regarding existing sustainability regulations — Full compliance with each market requirement in Design on sustainable construction in each market, and be in position to influence these — Update library of regulations and client requirements and Delivery regulations in each market Low carbon R&D systems — Develop and use low-carbon façade systems in at least — Project that uses our next generation of Hybrid Unitized in 50% of our projects - these systems should satisfy low Façade (HUF) systems is under construction carbon footprint and high thermal insulation requirements Long-term engagement — Manage the façade lifecycle through value added services, — Develop a façade service model for long-term engagement replaceable skins and IoT solutions beyond the warranty and after-warranty period — Focus on the integration of real-time data obtained via sensors in the façade into the digital twin Circular economy — Develop façade systems that satisfy the requirements — Calculate and compare the disassembly rating of state-of- of design for disassembly and reuse, and use these systems the-art unitized façade systems, and identify which design in projects changes are required — Achieve Zero Waste in-house and on-site — Zero plastic waste on-site — Increase the efficiency of material use by deploying optimization tools in 3D design, and tracking material flow in the ERP system — Achieve a 5% reduction of aluminium leftovers with the help of standardised design solutions

Corporate Sustainability Go to contents 21 Climate Protection Product carbon footprint — Have the automated measurement of project-specific CO2 — Extend our internal database of Environmental Product footprints as a standard performance criteria Declarations and CO2 emissions — Store CO2 emissions data in the internal ERP system — Automate embodied carbon assessment at the tender stage Value chain carbon — Annually measure scope 1, 2, and 3 emissions — Assess scope 1,2, and 3 emissions according footprint analysis — Develop carbon reduction targets to GHG Protocol — Define carbon reduction targets and corresponding reduction measures Sustainable Education and training — Foster a sustainability mindset within our employees — Organise two Knowledge Club sessions dedicated to Organisation — Nurture a culture of learning which includes talent sustainability development, career promotion and reskilling — Increase the number of training hours per employee by 40% — Increase the ratio of promoted employees by 1% Cross-functional teams — Implement the Agile way of working in commercial projects — Scale our Agile framework, based on Releases, across — Achieve a high level of Agile maturity through self-managing the organisation teams and a changed role for management — Use Agile scoring, as well as client satisfaction and project team satisfaction, to monitor how Agile is being implemented Diversity and Inclusion — Celebrate diversity and practice inclusion by providing equal — Maintain equal conditions for employees in the same employment opportunities position, regardless of nationality, cultural background, gender or age Engagement — Maintain and strengthen employee engagement — Increase employee engagement by 6% — Create meaningful social impact by supporting the — Support 6 disadvantaged families, including community we work in with our charitable activities the renovation of their homes — Increase employee involvement — Support 47 disadvantaged children in our philanthropic activities — Increase employee involvement in our charitable activities by 5%

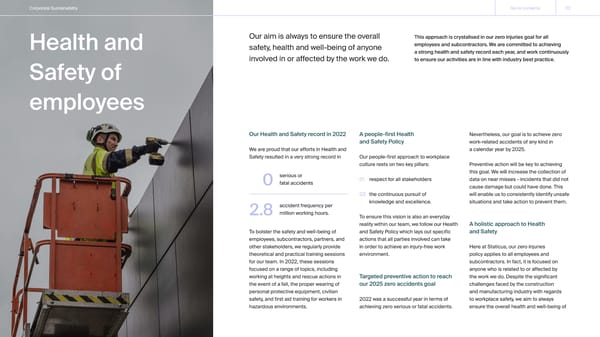

Corporate Sustainability Go to contents 22 Our aim is always to ensure the overall This approach is crystalised in our zero injuries goal for all Health and safety, health and well-being of anyone employees and subcontractors. We are committed to achieving a strong health and safety record each year, and work continuously involved in or affected by the work we do. to ensure our activities are in line with industry best practice. Safety of employees Our Health and Safety record in 2022 A people-first Health Nevertheless, our goal is to achieve zero and Safety Policy work-related accidents of any kind in We are proud that our efforts in Health and a calendar year by 2025. Safety resulted in a very strong record in Our people-first approach to workplace culture rests on two key pillars: Preventive action will be key to achieving serious or this goal. We will increase the collection of 0 fatal accidents 01 respect for all stakeholders data on near misses - incidents that did not cause damage but could have done. This 02 the continuous pursuit of will enable us to consistently identify unsafe accident frequency per knowledge and excellence. situations and take action to prevent them. 2.8 million working hours. To ensure this vision is also an everyday reality within our team, we follow our Health A holistic approach to Health To bolster the safety and well-being of and Safety Policy which lays out specific and Safety employees, subcontractors, partners, and actions that all parties involved can take other stakeholders, we regularly provide in order to achieve an injury-free work Here at Staticus, our zero injuries theoretical and practical training sessions environment. policy applies to all employees and for our team. In 2022, these sessions subcontractors. In fact, it is focused on focused on a range of topics, including anyone who is related to or affected by working at heights and rescue actions in Targeted preventive action to reach the work we do. Despite the significant the event of a fall, the proper wearing of our 2025 zero accidents goal challenges faced by the construction personal protective equipment, civilian and manufacturing industry with regards safety, and first aid training for workers in 2022 was a successful year in terms of to workplace safety, we aim to always hazardous environments. achieving zero serious or fatal accidents. ensure the overall health and well-being of

Corporate Sustainability Go to contents 23 everybody involved. — Health and safety management. Our dedicated in-house management In addition to safety, the measures Staticus is supported by specialised health and currently has in place also take into safety consultants that help us to ensure account workplace stress, mental health, that all our work is up to standard. and long-term health hazards posed by environmental factors like dust, noise, and — Health and safety measures to prevent poor ergonomics. accidents and injuries on construction sites and the factory floor, we have put Risk factors like noise, ergonomics, lighting in place effective measures in the areas and workplace stress are measured, and we of production, storage, transportation, carry out continuous risk assessments. delivery and installation. — Safe work methods. All our employees Health and Safety management are instructed and trained in safe work and measure methods, including lifting technique and working near the edge on open Staticus has adopted a comprehensive set structures that pose an increased fall of measures and methods to create a safe risk. Additional competence certificates working environment that is compliant with held by Staticus include ISO 14001, all relevant regulations. ISO 45001, Achilles, CHAS, and Constructionline. Our aim is to always ensure the overall safety, health and well- being of anyone involved in or affected by the work we do. This approach rests on two key pillars: respect for all stakeholders, and the continuous pursuit of knowledge and excellence.

This is a modal window.

Corporate Sustainability Go to contents 24 Active philanthropy Our charity initiatives Home renovations Raguvėlė Children’s Day Centre Activities related to the war in Ukraine In 2022, we marked the 5 year In 2022, Staticus continued its support We reacted quickly and decisively to help anniversary of our initiative to take care of for the Raguvėlė Children’s Day Centre families affected by the war in Ukraine. We disadvantaged families by renovating their in Anykščiai. This centre supports more provided direct support to families that homes. This year, we helped a household in than 20 children, aged between 6 and managed to escape the war. the district of Panevėžys by replacing their 17, who come from socio-economically windows. These were manufactured and disadvantaged backgrounds. The funds and We partnered with Save the Children to installed just before Christmas, and we are support we provide ensure the centre has provide urgent aid, and also supplied continuing to improve this family’s home the materials it needs for its learning and medical equipment directly to Ukraine. by making sure they have access to clean extra curricular activities. These medical shipments were collected water at home. together with our partners. This support for the centre has a long We have now provided 5 families with better history - we have previously contributed living conditions. We also provide annual funds to help repair the centre after a fire, support for these families, ensuring they and we are in regular contact with the can celebrate the biggest holidays of the centre’s founder to see if further support Gifts for children year with plenty of festive food and presents is needed. We take our responsibility to support the societies we for their children. On the major holidays of the year, and work in very seriously. That is because we understand Another important development this year important events like the first day of that a sustainable future is only possible when society was a new partnership with aid and charity school, we send gifts to 45 children. They fund Gėrio trupinėlis. Our philanthropic activities in 2023 receive toys, books and tasty treats to is supported. As a result, our people-first approach bring happiness and joy on these special extends beyond our own team and partners to We are committed to supporting our local occasions. communities. In 2023, we will continue to include a range of philanthropic activities. support disadvantaged children and families.

Go to contents 25 R&D Activities and Digitalization 04 Major steps forward in key R&D projects in 2022 A new framework for Agile Digitalizing Staticus

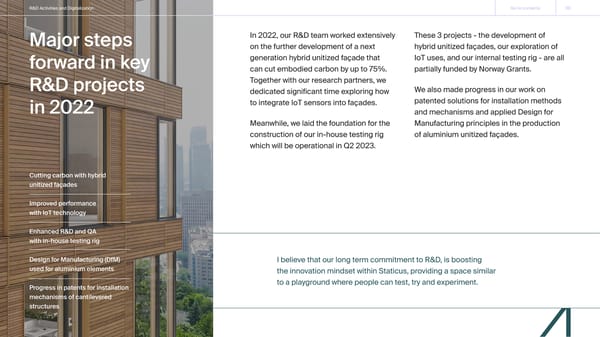

R&D Activities and Digitalization Go to contents 26 Major steps In 2022, our R&D team worked extensively These 3 projects - the development of on the further development of a next hybrid unitized façades, our exploration of forward in key generation hybrid unitized façade that IoT uses, and our internal testing rig - are all can cut embodied carbon by up to 75%. partially funded by Norway Grants. R&D projects Together with our research partners, we dedicated significant time exploring how We also made progress in our work on in 2022 to integrate IoT sensors into façades. patented solutions for installation methods and mechanisms and applied Design for Meanwhile, we laid the foundation for the Manufacturing principles in the production construction of our in-house testing rig of aluminium unitized façades. which will be operational in Q2 2023. Cutting carbon with hybrid unitized façades Improved performance with IoT technology Enhanced R&D and QA with in-house testing rig Design for Manufacturing (DfM) I believe that our long term commitment to R&D, is boosting used for aluminium elements the innovation mindset within Staticus, providing a space similar to a playground where people can test, try and experiment. Progress in patents for installation mechanisms of cantilevered structures

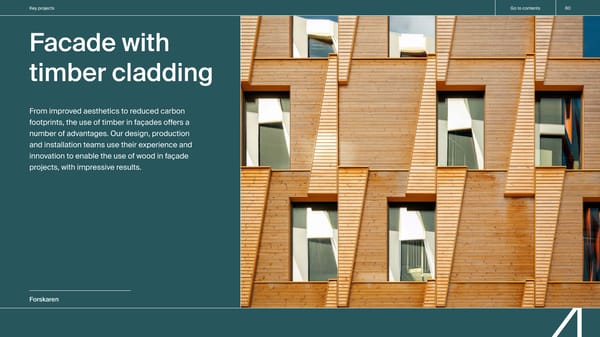

R&D Activities and Digitalization Go to contents 27 Cutting carbon with hybrid unitized façades In the EU, buildings are responsible for aluminium unitized façade. Importantly, 40% of all energy consumption and 36% of there is no compromise in terms of greenhouse gas emissions. This means the performance. In fact, areas like thermal façade industry has an important role to play performance are actually improved, in the reduction of CO2 emissions. resulting in higher user comfort. Staticus is working continuously on Focuses for 2023 reducing the carbon emissions of façade systems, most notably through the In 2023, we will focus on testing our hybrid development of a next generation of hybrid unitized façade and making ongoing unitized façades. In this project, our R&D improvements. Its system performance will team is using its decades’ of expertise to be tested at a registered body, and we will replace high embodied carbon materials in receive the results in early Q2 2023. façades with low-carbon alternatives such as timber. This testing is important because increasingly unfavourable weather, resulting Key achievements in 2022 from climate change, means building façades are subject to higher requirements. In 2022, we finished the design This includes water and air tightness, load development process of our hybrid unitized resistance, soft body impact, and acoustics. façade system. Testing also enables us to make continuous In this façade system, structural mullions improvements to our hybrid unitized façade, and transoms are replaced with GLULAM and this capability will be enhanced by the wood. Recycled aluminium is used in completion of our in-house testing rig in the frame. At the product stage (A1-A3), 2023. this saves 1.3 kg of carbon for every 1 kg of GLULAM timber used. Furthermore, We firmly believe that hybrid unitized façade embodied carbon is cut from 8 kg to 2.3 kg systems are future oriented, since providing for every 1 kg of recycled aluminium used. low carbon solutions in conjunction with long-term durability and well-being. In total, embodied CO2 is reduced by up to 75% when compared to a standard Hybrid Unitized Façade / Interior

R&D Activities and Digitalization Go to contents 28 Improved performance Enhanced R&D and with IoT technology QA with in-house Key achievements in 2022 testing rig Staticus’ R&D team is exercising ways to integrate Internet of Things (IoT) technology In 2022, we worked on building the physical Funded by the 2014-2021 Norwegian Key achievements in 2022 in our façades with the goal of enhancing and software components required to Financial Mechanism Program “Business Our activities in 2022 were focused on the building performance, and reducing have a fully functioning façade monitoring Development, Innovation and SMEs” EEA design and planning for this rig. Production maintenance costs. Achieving this can have application. This application will be used and Norway Grants, we are constructing a of the rig began in the later part of the year. a significant impact on carbon emission by the Staticus Care team to identify and testing rig on our premises in Vilnius. In Q4, the steel parts were successfully reduction over the lifetime of a building. address potential issues using a predictive fabricated, pre-assembled for quality maintenance system. The additional rig with a larger capacity inspection at their manufacturing plant. The team is developing façades with will be operated by the Project Technology integrated sensors. These sensors deliver Our project partner KTU worked on creating Unit team. They will continue to ensure real time data to a digital twin, allowing the digital twin concept, which is now in the that every Staticus project is verified via us to monitor façade performance. Once final stages of development. Meanwhile, physical testing both before production Focuses for 2023 this data is integrated into the building OsloMet and SINTEF, who are also project begins, and throughout the production In January 2023, the steel parts arrived management system (BMS), the BMS can partners, continued with the development process. at our facility. be optimised for improved energy use and of a predictive model to alert Staticus Care faster responses to changing conditions personnel of potential non-conformance The team will be able to use this rig for Construction and calibration of the rig will or potential issues. This is because our issues in the hybrid unitized façade. Our visual mock-ups as well as performance be completed in Q2 2023. sensors are able to collect data that is partners ADD Business Solutions worked on testing. The rig is large enough to otherwise unavailable to traditional BMSs, the development of the cloud platform that accommodate over-size units and creating much richer datasets. will ingest, store and process the collected enable us to run full test sequences in sensor and weather data. accordance with CWCT and European Another important advantage of IoT is standards at our premises. It will also related to façade end of life and component Focuses for 2023 further enhance our in-house quality I believe that these activities, and our reuse. By tracking and archiving information control and quality assurance programme. long term commitment to R&D, is boosting on components in our digital twin library, we Our goal for 2023 is to integrate all of these Furthermore, it will be a valuable asset for “ will be able to accurately determine which components into a user friendly online and our R&D and prototyping work, allowing the innovation mindset within Staticus, components are still reusable. We can mobile platform. This platform will stream our engineers to quickly collect a range providing a space similar to a playground where then plan for their retrieval and reuse. This live data from our IoT mock-up, providing us of testing data without having to leave will allow us to have an impact on parts of with proof of concept. Staticus’ facility. people can test, try and experiment. the value chain that we are not yet directly involved in. Aušra Vankevičiūtė, Group CEO, Staticus

R&D Activities and Digitalization Go to contents 29 Design for Manufacturing Progress in patents for (DfM) used for aluminium installation mechanisms elements of cantilevered structures Design for Manufacturing (DfM) refers Using our DfM system, we will take full There is an increasing demand on exterior to the process of designing parts, control over the production of profiles in structures and features outboard of the components or products with ease of collaboration with an extrusion company. façade. To avoid scaffolding and disruption manufacturing in mind. The end goal System is supplied with full EN and of the safe and fast unitized curtain is to make a better product at a lower CWCT test certifications for performance wall installation, Staticus developed an cost and higher efficiency, thus more compliance. installation mechanism for cantilevered environmentally friendly, and this is structures, allowing for direct load transfer achieved by simplifying, optimising In this way, we are applying DfM, optimising to the building structure. and refining the product’s design. the production process through an iterative process with design. Staticus has developed a LT patented Staticus aims to use DfM increasingly solution related to the equipment and in its façade projects. Focuses for 2023 methods used to attach such structures. It permits the exterior cantilevered structure Key achievements in 2022 We have already started designing the to be fine adjusted once it is securely façade elements for the Separatorn 1 installed in place. In 2022, Staticus reached a major R&D project. Mock-ups, testing and production milestone by launching our own system for are planned for Q1 of 2023, and installation Achievements of 2022 and focuses designing and creating unitized aluminium is set to start in June. for 2023 systems. Through this project we are able to assess We have already received a national patent This system was already put into use on how our cross functional collaborative team for this innovation in 2022. the Separatorn 1 building in Flemingsberg, work takes shape, and continue to further Southern Stockholm. For this project, we optimize the Design for Manufacturing In 2023 we are focusing on build and install a 7,000 sq. m. unitized processes. the implementation of the customised aluminium façade that is unique for its exterior design solutions, by having curved corners. an efficient installation method and mechanism in place.

R&D Activities and Digitalization Go to contents 30 Global markets and supply chains are To meet these needs and ensure we remain A new changing rapidly. Furthermore, project a resilient business in a changing landscape, demands are increasing in terms of we must be faster and more flexible than framework sustainability, aesthetics and building ever. Our continued evolution as an Agile performance. organisation is fundamental to this. for Agile Our journey to becoming We understood that these could be solved some staff experienced, and ensure a an Agile organisation by applying more Agile principles. common approach to planning within the company. In 2019, Staticus defined 5 key strategic — Client-centricity is a critical element directions for its development. One of these of the Agile methodology, and we — We could encourage more self- was to embrace Agile methodology and understood that we could ensure greater reflection and continuous learning using become an Agile organisation. orientation towards the customer by the Agile principles of Inspecting and building Strong and regular collaboration adapting, and Looking for continuous The goal was to improve our business with customers and stakeholders, and improvement. This would be especially resilience. We wanted to further strengthen embracing the principles of Transparency impactful when combined with Working trust and communication between teams and Adapting to change. in iterations. while making our planning more effective, and enhancing our ability to manage — We could use the Agile principle of change. Transparency to ensure team members Key achievements in 2022 - always had a clear understanding A new Agile framework Our journey to becoming an Agile of the overall situation in the whole organisation started with our project company, and understood the purpose In the Summer of 2022, we worked closely realisation teams. Having cross-functional and direction of individual teams and with our project realisation teams to apply teams is one of the main principles of Agile, divisions. these Agile principles. We also held a so we made these teams cross-functional. series of workshops with different teams, — Working in iterations, combined with during which we identified other pain However, we noticed that we still had some Transparency, could address the lack points that Agile could be used to address. issues with our ways of working. of clarity around roles and responsibilities Tottenham Hale Works | London, United Kingdom

R&D Activities and Digitalization Go to contents 31 Based on the output of these workshops, Focuses for 2023 and our analysis of the initial issues the project realisation teams had experienced, 2023 will be dedicated to the we prepared a new Agile Framework for implementation and monitoring of this Staticus. framework, and the scaling up of Agile across our organisation. The main idea of this framework is for us to work in short iterations called Releases, and This framework will ensure there are then to periodically apply the relevant Agile common planning practices across the ceremonies. organisation, and that work is undertaken at one pace. It will also facilitate In Staticus’ Agile framework, one Release transparency within all our teams, and a is equal to one calendar quarter. Each feeling that we are all “on the same page”. Release starts with a Release planning meeting where we define key focus areas This framework will assist us in setting for the upcoming quarter. We also identify better priorities and will help each team key results, roles and responsibilities, member to understand how they can and ways of working (or WoW). A Release contribute to the goals of their team, and is then divided into 2-week Sprints with of the company as a whole. In this way, this stand-up meetings for status reporting. framework will help us become a purpose Feedback from both internal and external driven organisation. stakeholders is collected regularly. At the end of each Release, all teams will conduct a Release review and there will also be a team retrospective to ensure continuous improvement.

R&D Activities and Digitalization Go to contents 32 Digitalizing In 2022, we continued the ongoing digitalization of our working processes, and enhanced our Staticus client centricity with new reporting tools. Here is a breakdown of the main digitalization projects that were initiated or continued by Staticus in 2022: 01 02 03 E.Warehouse Scanning 4D reporting tool CostX tool connected and Barcoding ongoing with PowerBI a) Issue: Our existing reporting tools had progress. For example, it has been used to a) Issue: The process of manually managing limitations that made it challenging for successfully improve communication and a) Issue: Changing material costs have large amounts of stock in the warehouse stakeholders to monitor projects in a transparency in the K8 building project in made the task of calculating project was inefficient and provided space for fast, intuitive manner. The need to input Stavanger, Norway. budgets and preparing offers challenging. errors. data manually, a lack of regular updates, It is also difficult to make the information and the inability to easily filter data were Our clients have recognised our 4D on estimation easily accessible. b) Achievements: Our e.warehouse all problematic. This inhibited the early reporting tool as an important innovation system,which was piloted in late 2021, identification of potential issues and that is fundamental to the detailed b) Achievements: In 2022, our Commercial was implemented throughout our made communication between parties monitoring of projects. It saves time and Division started using the CostX tool to warehouse in 2022. more difficult. improves planning. All stakeholders have ensure the standardisation of project benefitted from the tool’s ability to refresh calculations and improve the efficiency This barcoding and scanning solution, b) Achievements: In 2022, we introduced automatically as it collects data from of offer preparation. which helps to ensure proper stock our new 4D reporting tool. It connects various systems, and its wide variety of management, is now live for 75% of our detailed 3D models of our projects with filters for interacting with the reports. This tool, which integrates with the general materials groups. data - including BIM data - from various reporting tool PowerBI, also makes ERP (Enterprise Resource Planning) We look forward to further improving our the offer preparation process easily This successful roll out, combined with the and CDE (common data environment) client-centricity by using our 4D reporting traceable, from the estimation stage continuous work on our Material Movement systems via the VCAD tool in Power BI. tool in all projects, and upgrading it to through to budgeting. Now information Programme, has enabled us to have more include even more data sources and is easily accessible for project managers transparency in the process of ordering This tool has made it easier to bring all functionality. and key stakeholders. from warehouse leftovers, and increased stakeholders up to date on a project’s the efficiency of materials usage.

Go to contents 33 Key projects 05 Hospitals Closed Cavity Refurbishment Highrise buildings Wood

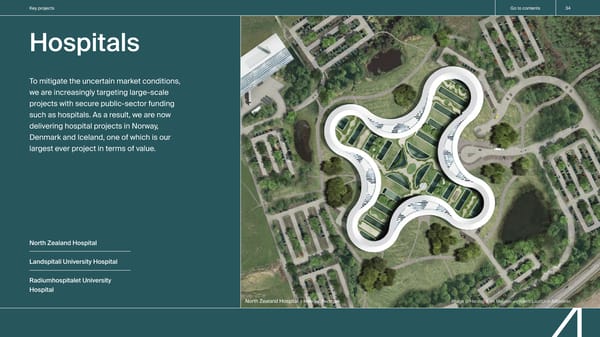

Key projects Go to contents 34 Hospitals To mitigate the uncertain market conditions, we are increasingly targeting large-scale projects with secure public-sector funding such as hospitals. As a result, we are now delivering hospital projects in Norway, Denmark and Iceland, one of which is our largest ever project in terms of value. North Zealand Hospital Landspitali University Hospital Radiumhospitalet University Hospital North Zealand Hospital | Hillerød, Denmark Image © Herzog & de Meuron – Vilhelm Lauritzen Arkitekter

Keyprojects | Hospitals Go to contents 35 North Zealand Hospital Hillerød, Denmark Client: NCC DK Architects: Herzog & de Meuron and Vilhelm Lauritzen Category: Medical 2 Façade area: 20 000 m Type of façade: Unitized & stick façades Type of Construction: New construction Investor: Capital Region of Denmark Image © Herzog & de Meuron – Vilhelm Lauritzen Arkitekter

Keyprojects | Hospitals Go to contents 36 North Zealand Hospital The units are fully cladded with wood elements. In total, we are using around 14 000 m2 of naturally treated wood for this project. This wood cladding is the main The North Zealand Hospital in Hillerød, Denmark, is a Danish way the building visually connects with the surrounding nature, and it is also important “super hospital”. Designed by Herzog & de Meuron and Vilhelm in reducing the carbon footprint of the Lauritzen Architects, it will be one of the largest hospitals in the project. country, with about 20 clinical departments to serve 300,000 local citizens. It features unique architecture that is a response to The use of wood presents challenges in terms of both design, production and the surrounding countryside. The organic, flexible shape of this installation. For example, the design and 4-storey, 118,000 m2 building helps to connect patients to nature. production of the thermal pine boards that cover the type D elements was technically difficult. In terms of installation, one major challenge is the vertical wood boards that will be placed at each junction of the Type D elements. There is a different overlap of the Furthermore, the project has high producing and installing approximately boards around the entire perimeter of the performance requirements. The building 2020 elements. There are two different building, which means approximately 80% has been designed to meet the Danish types of elements (named type A and of the elements have different layouts for Building Classification 2020, and DGNB type D), and they are completely different the wood boards. gold certification is being targeted, which from each other, because of different will make this one of the most energy- profiles systems used. One type has 90 The large size of the elements also required efficient hospitals ever to be built. degrees corners, is two storey height with the installation team to think innovatively. wood lamellas and aluminium fin profiles The type A elements are up to 2.5 m wide The 20,000 m2 building envelope that as a cladding, while the other is faceted and 8.3 m high, and the type be elements Staticus is creating and installing is an to match the curved path of the higher are up to 2.7 m wide and up to 7 m high. architectural statement in itself. It has high- section of the building and has a shiplap Given these dimensions, the high number performance requirements, but also serves board cladding. However, both façade of corners, and the curved upper part of the important practical and remedial functions. types are bottom supported. building, the team is using a robotic forklift It will provide for a comfortable interior for installation. This ensures elements are environment, and blur the lines between Another complexity in this project is moved and calibrated correctly. interior and exterior. the high acoustic requirements for the horizontal and vertical flanking insulation North Zealand Hospital is estimated to be For the Staticus team, this is both a large- between rooms and floors. completed in 2027. scale and complex project. In total, we are Image © Herzog & de Meuron – Vilhelm Lauritzen Arkitekter

Keyprojects | Hospitals Go to contents 37 Landspitali University Hospital Reykjavik, Iceland Client: NLSH Architect: Corpus 3 (Iceland) Category: Hospital Façade area: 30 000 m² Type of façade: Unitized & stick façades Year of completion: 2027 Image © Corpus 3

Keyprojects | Hospitals Go to contents 38 Landspitali University Hospital The new Landspitali University Hospital in Reykjavik, Iceland will be the largest single building in the country. In terms of its value, this is also Staticus' largest ever project. In 2022, Iceland's Minister of Health and our CEO Aušra Vankevičiūtė signed a contract for the façade design and contract work with a value of €47 million. Staticus' team is responsible for the Landspitali Hospital is Staticus' first project design, production and installation of the in Iceland, and the country's extreme curtain wall, which is around 30,000 sq. weather and seismic conditions also present m. in size. It includes glass roofs, doors, challenges. We will conduct extensive off and rainscreens, and ceilings. on-site testing to ensure our façade is able to meet seismic requirements and can cope Naturally, the large scale and scope of with high wind loads. this project will present the Staticus team with many challenges to overcome. Another notable aspect of this project is Moreover, the execution time for this that there is no general contractor. This project is fairly short. Production is places a higher responsibility on us to be planned to start in July 2023. The façade proactive in finding solutions together with elements will be transported by ship from the project owner and other contractors. Our our production facility to Iceland in time Agile process management and effective for installation to begin in September communication will help us to achieve this. 2023. November 2024 is the target date for completion of the façade. Landspitali Hospital is estimated to be completed in 2027. Image © Corpus 3

Keyprojects | Hospitals Go to contents 39 Category: Hospital Radiumhospitalet Façade area: 19 728 m2 Type of façade: Unitized & stick façades Investor: Helsebygg Year of University Hospital completion: Ongoing Oslo, Norway Client: HENT AS Architects: Henning Larsen Photo © Henning Larsen

Keyprojects | Hospitals Go to contents 40 Radiumhospitalet is Norway's specialist hospital for the treatment of cancer, and is also Northern Europe's largest cancer centre. A new, four-part clinic is being built next to the existing hospital, where proton therapy - a new type of radiation therapy for cancer - will be carried out. The new clinic is being built on the same site necessary speed of façade production as the current Radium Hospital. Construction and installation. is taking place on a narrow building site close to the existing hospital, while the hospital is Another notable challenge with this in full operation throughout the construction project is the very high fire protection period. The new facility will have connection standards required. To meet these points to the existing building stock, which standards, our team has offered a number will continue to be part of the hospital. of atypical fire protection solutions. Staticus' scope of work for this project is Some elements have been produced wide and complex. The project features two to meet strict EI60 and EI30 class fire different elemental façade systems and protection requirements. Furthermore, three different element cladding types, plus there is the fire-resistant stick façade fire resistant elements and stick façades. that was installed in the courtyard of the Moreover, the ventilated façades have three building. Image © Henning Larsen different types of cladding and several different fillings. Staticus' work also includes Another factor is the specific acoustic glass roofs, steel-aluminium doors, and requirements. In order to fulfil the client's Radiumhospitalet ceilings. In total, we are designing, producing requirements to the fullest, we consulted and installing 12 095 m2 of elemental façade, with various institutes and companies 484 m2 of stick façade, 1 355 m2 of ceilings specialising in this field, such as University Hospital (soffits), and 5 664 m2. of ventilated façade. Anderson Acoustics. Delivering such a diverse remit requires the The Radiumhospitalet project is planned Oslo, Norway entire team to adapt quickly to maintain the to be finished in September 2023.

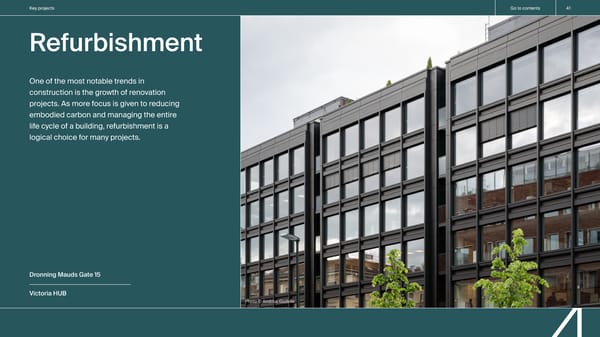

Key projects Go to contents 41 Refurbishment One of the most notable trends in construction is the growth of renovation projects. As more focus is given to reducing embodied carbon and managing the entire life cycle of a building, refurbishment is a logical choice for many projects. Dronning Mauds Gate 15 Victoria HUB Photo © Andrius Gudelis

Keyprojects | Refurbishment Go to contents 42 Category: Office building Dronning Mauds Façade area: 8 300 m2 Type of façade: Unitized & stick façades Type of Construction: Renovation Gate 15 Certifications: BREEAM-NOR General Contractor: AF Gruppen AS Oslo, Norway Investor: Nordea Liv Eiendom Client: AF Gruppen AS Architects: DARK Arkitekter AS Photo © Andrius Gudelis

Keyprojects | Refurbishment Go to contents 43 Dronning Mauds Gate 15 is an office building located in a prime spot in Oslo’s central business district. It has been renovated to ensure it has an even higher energy efficiency performance, while at the same time retaining the building’s architectural features and overall aesthetic. Staticus was tasked with designing, total heat transfer coefficient is expected producing and installing 225 prefabricated to be approximately 0.69 W/m²K for 73% façade elements for this renovation. of the glazing area. Staticus also chose Unusually, the replacement of the existing to apply an easily recyclable, natural zinc curtain wall with new façade elements had cladding application because zinc is a non- to happen with the building still occupied. ferrous, self-protecting metal. Life Cycle Furthermore, the right balance had to assessment (LCa) modelling gives it be achieved between preserving the a Certified Environmental Profile and a existing aesthetic of the building, which is Green Guide rating was produced. characterized by continuous window bands and repetitive modules, while at the same The short lead-in time for this project time improving the performance of the also posed challenges. In less than 2 building envelope. As a renovation project, months, the production team was able to design solutions were required to navigate successfully assemble the façade units. the steel reinforcements and beams that This speed was aided by the fact that units get in the building envelope’s way, and the within Staticus’ typical range of sizes were exposed interior and exterior constructive selected, facilitating faster production, framework. logistics and installation. With limited time on site, installation also needed to Photo © Andrius Gudelis One of the most important aspects of this be carefully coordinated. Despite these project was to achieve a very high level of challenges, Staticus delivered a building energy efficiency. The building already had envelope with higher performance specs Dronning Mauds Gate a "BREEAM In-Use: Very Good" rating, but and an aesthetic consistent with the original even higher standards, including a typical building, all installed with minimal disruption heat transfer coefficient below 0.7 W/ to the building’s tenants. (DMG) 15 m²K for approximately 70% of the glazing area, were required. The Staticus team Implementation of the project was opted for double-skin, cover-caped, triple completed in 2022. Oslo, Norway glazed, unitised façade elements, and the

Keyprojects | Refurbishment Go to contents 44 Category: Office building with retail space Victoria HUB at ground level Façade area: 11 472 m2 Type of façade: Unitized & stick façades London, UK Unitized façade: 3,835 m2 (654 panels) Stickwork 3,117 m2 Client: McLaren Construction Group Curtain Wall: Architects: Morrow + Lorraine Ltd. Other types 4,496 m2 (rainscreen, u-type glass cladding, balustrades, soffits, automatic opening vents “AOVs”): Type of Refurbishment with 3 additional Construction: levels extension on a rooftop Certifications: BREEAM-UK ‘Excellent’ certificate Investor: Gaw Capital Advisors (UK) Ltd Image © Morrow+Lorraine Architects